importance of torsion test for engineering materials|metal torsion testing : bulk Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and . 8 de nov. de 2022 · Você pode gostar. 1.6M curtidas,29.6K comentários.Vídeo do TikTok de Juana Ocio (@juanaocior): "um pouco da minha #transição / TikTok eu já tenho 18 anos!!! .

{plog:ftitle_list}

Resultado da Martina Oliver com perfil no Privacy faz vídeos aparecendo totalmente nua pelada, ser exibindo, com as amiguinhas e ate transando em deliciosas .

Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and .

The purpose of torsion testing is to analyze the mechanical behavior of a material when subjected to twisting forces. It helps determine the material's shear .Performing a torsion test is a crucial process in materials testing, helping engineers and scientists understand a material’s response to twisting forces. To conduct a torsion test, follow these steps: Sample Preparation: Begin by . Torsion testing requires the twisting of a specimen along its primary axis and is a practical test for acquiring mechanical property data like torsional shear stress/strain, maximum torque, shear modulus, and breaking .The purpose of a torsion test is to determine the behavior a material or test sample exhibits when twisted or under torsional forces as a result of applied moments that cause shear stress about the axis.

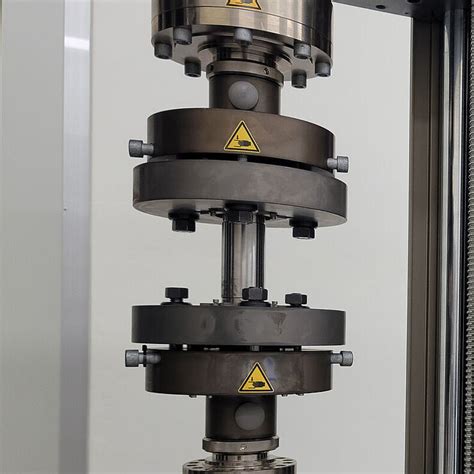

The Axial-Torsion Test (biaxial test) stands as a vital procedure in material science and engineering, encompassing a broad spectrum of materials like metals, polymers, ceramics, and composites. By simultaneously applying axial .Understanding the behavior of materials under torsional stress through torsion testing and accurate torque measurement is crucial in engineering. This knowledge informs various .

what is torsional testing

The purpose of this exercise is to obtain a number of experimental results important for the characterization of materials. In particular, the results from the torsion test will be compared .Statics - Twisting Moments. Twisting moments, or torques, are forces acting through distances (“lever arms”) so as to pro- mote rotation. The simple example is that of using a wrench to tighten a nut on a bolt as shown in Figure 6: if the .The Axial-Torsion Test (biaxial test) stands as a vital procedure in material science and engineering, encompassing a broad spectrum of materials like metals, polymers, ceramics, and composites. By simultaneously applying axial .

Axial-torsional testing is crucial for validating the real-world performance of materials or products that undergo rotational motion when in service. Torsional testing is conducted to assess how a product or material will respond to the stress of repeated twisting motion.Background Many traditional experimental testing devices like hydraulic testing machines, Split Hopkinson bar technique, etc. are available to recreate the same material behaviour that occue during manufacturing processes at different strain rates. But the fact is that a state of large equivalent strain with dominant shear strain at intermediate strain rate is not easily achievable . Why is Material Testing Important in the Manufacturing? . The torsion test helps determine material properties, including shear strength, torsional strength, and torsional modulus of elasticity, especially when designing components like turbine blades, drive shafts, and gears subjected to twisting loads. . it becomes unusable after the test . where L 0 is the initial gage length and ΔL is the change in gage length (L − L 0).. Multiple detailed descriptions of a typical stress–strain diagram is presented in the literature, e.g., in [].The most important aspect relevant in mechanical engineering is segments shown by numbered points in Fig. 3b. When a solid material is subjected to small stresses, the bonds .

Full syllabus notes, lecture and questions for Torsion - Strength of Materials (SOM) - Mechanical Engineering - Mechanical Engineering - Plus excerises question with solution to help you revise complete syllabus for Strength of Materials (SOM) - Best notes, free PDF download

The MES mechanical test team provides torsion testing of fasteners, rods, tubes, and other components. Torsion testing provides material performance when subject to twist and shear loads. The sample is rigidly anchored at one end of the sample, while torsional loads are applied as a moment to the other end. To perform Torsion Test on. Mild steel specimen; Cast iron specimen; Purpose: To study the shear stress ~ shear strain behavior of the material. To study the failure pattern of these materials in torsion. To determine the mechanical properties, e.g, Modulus of elasticity, Modulus of rigidity, Shear strength, shear strain and ductility in . The torsion testing equipment which was used in the previous torsion test was also used in this study. Figure 1 shows an image of the stereo camera system and the inclinometer used in this study. The photogrammetric system consists of a pair of Basler Pilot piA2400-17gm cameras, Computar (M2518-MPW F1.8) Megapixel lenses, two LED light units .What is the importance of Shear Testing? Shear testing is of paramount importance in the field of material science and engineering, as it helps determine a material’s behavior under shear stress—internal sliding forces acting parallel to each other. Understanding the shear properties of a material is crucial for various reasons:

DEPARTMENT OF MECHANICAL ENGINEERING MATERIAL TESTING LABORATORY I - CYCLE 1. Izod Test 2. Brinell Hardness Test 3. Shear Test 4. Bending Test II – CYCLE 5. Charpy Test 6. Rockwell Hardness Test 7. Torsion Test 8. Compression Test III– CYCLE 9. Heat Treatment 10. Tensile Test IV – CYCLE 11. Wear Test 12. Micro Structure A compression test reveals how a material behaves when under a crushing load until it deforms or fractures. These tests can provide valuable information about a material’s compressive strength and other properties. A compression test is an important test to understand how a material will behave during metalworking.

Predicting Material Failure: By simulating the repeated stresses a material will face in real-world applications, Fatigue Testing allows engineers and scientists to predict when and how a material might fail. This understanding is vital in designing components that will not fail unexpectedly. So it is compulsory for an engineer to understand the basics of torsion theory and learn how a material of engineering component will act under torsion stresses. (pg 120-121) R.S. Khurmi & J.K. Gupta (2005) stated . The beam bending test is a test that is conducted by applying a force on a test specimen to bend the material. When conducting a bending test the material can either be simply supported or cantilevered. Regardless of .For a ductile material, the fracture would be in shear (longitudinal, splitting) and for a brittle material, the fracture (also called helical fracture) would be tensile (45° splitting). Equipment This experiment is performed using The SM1001 30Nm Torsion Testing Machine shown in the figure below. Figure 2: SM1001 30Nm Torsion Testing Machine

Dr. S. E. Beladi, PE Mechanics of Materials Lab P a g e | 4 Experiment Two- Torsional test Use the following Suggested Table for gathering Data Torsion test Data Specimen Material Steel Distance D1 mm Distance D2 mm Test Date/ Time Rod Diameter mm Length Applied Load Measured Deflection Angle of Twist Radian Calculated Angle of Twist Modulus

I was reading the book Mechanics of Materials by Beer and Johnston.The author points out in torsion chapter that ductile materials generally fail in shear.And brittle materials materials are weaker in tension than in shear.From this they concluded that when subjected to torsion a circular shaft made of ductile material breaks along a plane perpendicular to it's . Buckling is an important topic that any engineer designing structures that carry compressive loads must understand. This page will guide you through the basics of buckling, from Euler’s formula for predicting the onset of buckling to more complex topics like slenderness ratios and inelastic buckling.So keep reading, or watch the animated video below, to get up to speed.

torsion test M M Special relations for isotropic materials: 2(1 +ν) E G = 3(1 −2ν) K = Elastic Bulk modulus, K: pressure test: Init. vol =V o. Vol chg. = ΔV P PP P = - K ΔV V o P ΔV K V o Comparison of Young’s moduli 0.2 8 0.6 1 Magnesium, Aluminum Platinum Silver, Gold Tantalum Zinc, Ti Steel, Ni Molybdenum Graphite Si crystal Glass . The chapter provides an introduction to mechanical engineering, covering fundamental concepts of mechanical properties of materials and their use in the design and manufacturing.

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain.It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined (see tensile testing).These curves reveal many of the properties of a material, such as the Young's .

It analyzes the elastic deformation, plastic deformation, and the effect of strain rate on plastic deformation. The article describes the theory of anisotropy in plastic torsion and the various components of a torsion testing machine. These include drive system, test section, torque and rotational displacement transducers, and rigid frame.

The notes and questions for Torsion - Strength Of Materials, GATE have been prepared according to the Civil Engineering (CE) exam syllabus. Information about Torsion - Strength Of Materials, GATE covers topics like and Torsion - Strength Of Materials, GATE Example, for Civil Engineering (CE) 2024 Exam. Find important definitions, questions . Figure 8. Torsion. Associated Activities Forces in Structures: Glue Sticks Bend & Twist - Students use glue sticks to demonstrate tension, compression and torsion. Assessment Questions: Evaluate students' understanding of the material, individually or as a group, using the Investigating Questions provided in the associated activity.Importance of Torsion of Shafts Mechanical Engineering: Understanding Torsion of Shafts is crucial for Mechanical Engineering exam success. Knowing its pattern, syllabus, and question paper analysis can significantly boost preparation. .

what is a torsion tester

WEB1 dia atrás · Siga o PORTAL DO ZACARIAS no Facebook, Twitter e no Instagram. Entre no nosso Grupo de WhatApp , Canal e Telegram Em nota, a pasta informou que as .

importance of torsion test for engineering materials|metal torsion testing